Table of Contents

Introduction

In the demanding world of precision manufacturing and industrial tool production, selecting the right material is paramount. Among the most frequently considered cold work tool steels are A2 and D2. Both are renowned for their impressive hardness and wear resistance, making them staples for a wide array of applications, from cutting and blanking dies to punches and intricate molds. However, despite their widespread use, an in-depth understanding of their distinct properties reveals critical application gaps where one may significantly outperform or underperform the other.

This blog post delves into five crucial areas where the nuanced differences between A2 vs D2 tool steel become apparent, guiding manufacturers and engineers toward more informed material choices that directly impact efficiency, durability, and cost-effectiveness. Understanding these gaps is essential for optimizing performance and avoiding costly mistakes in demanding industrial environments, where specific properties can make or break a project. Both A2 and D2 tool steel offer unique advantages, but recognizing their limitations for particular precision needs is key to success.

Understanding A2 vs D2 Tool Steel: The Core Differences

Before exploring the critical application gaps, it’s vital to briefly recap the fundamental characteristics that differentiate A2 vs D2 tool steel.

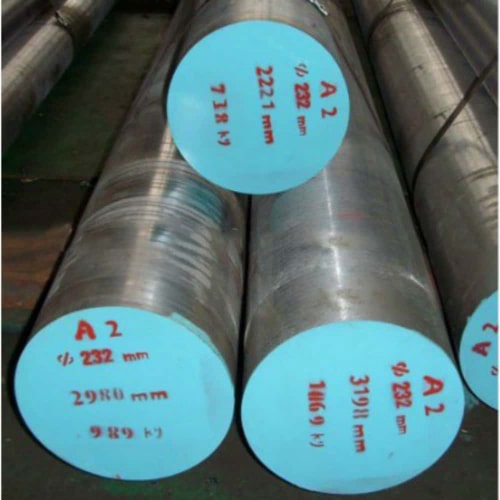

A2 tool steel is an air-hardening, medium-alloy tool steel known for its good balance of wear resistance, toughness, and dimensional stability during heat treatment. It offers improved surface finish and precision, coupled with high wear resistance. This makes A2 tool steel a versatile choice for applications requiring a good combination of properties without extreme demands in any single area.

D2 tool steel, on the other hand, is a high-carbon, high-chromium cold work tool steel. It is celebrated for its exceptional wear resistance and good compressive strength, often outperforming many other tool steels in abrasive conditions. However, its higher chromium content and carbide volume can lead to reduced toughness compared to A2, making it more prone to chipping or brittle fracture under certain conditions. D2 tool steel is often compared against other high-performance steels for its toughness and wear resistance.

Both A2 and D2 tool steel grades are part of the comprehensive range of tool and mold steels available from professional solution providers, who emphasize their excellent durability, cutting performance, and heat treatment stability through careful forging. These providers offer a wide range of processing services, including cutting, machining, heating, forging, and heat treatment, allowing for professional customization to meet different product needs. This deep understanding of material characteristics and applications is crucial for selecting the optimal tool steel and die steel solution based on intended use, production process, required strength, and budget.

Critical Application Gap 1: Toughness Limitations in High Impact Loads

One of the most significant distinctions between A2 vs D2 tool steel lies in their respective toughness levels, particularly under high impact or shock loading conditions. A2 tool steel, while generally tough, exhibits A2’s toughness limitations in extremely high impact load molds. For applications involving severe impact or high-frequency cycling, such as in certain precision stamping dies or blanking tools on continuous production lines, A2 steel can demonstrate fatigue failure modes of A2 steel in high-frequency impact molds. The moderate carbon content and alloying elements of A2 provide a decent compromise, but for truly extreme conditions, it may not suffice.

Conversely, D2 tool steel, with its higher carbide volume and enhanced wear resistance, often presents risk assessment of D2 tool steel in cold heading dies with extremely high toughness requirements. While D2 excels in resisting abrasive wear, its inherent lower toughness can make it susceptible to chipping or catastrophic failure when subjected to sudden, intense impact forces or repeated shock loads. This is particularly evident in applications like cold heading dies, where the material must withstand substantial compressive and impact stresses without cracking.

When designing precision stamping dies, the precision stamping die requirements for D2’s chipping resistance: A2’s alternative considerations and limitations must be carefully weighed. If the primary failure mode is expected to be chipping rather than abrasive wear, the slightly tougher A2, or even a different tool steel altogether, might be a more suitable choice.

The choice between A2 vs D2 tool steel in high-load cutting applications also influences analysis of D2 vs A2 tool steel life expectancy in high-load cutting applications. For applications where impact is a critical factor, engineers must consider whether the enhanced wear resistance of D2 justifies its reduced toughness, or if the moderate toughness of A2 provides a safer, more reliable solution. Often, a professional tool steel provider’s expertise in material characteristics and applications can guide this decision, offering tailored solutions based on the specific production process and required strength.

Critical Application Gap 2: Processing Challenges for Ultra-Fine Surface Finishes and Miniaturization

The pursuit of ultra-fine surface finishes and miniaturized components in precision manufacturing introduces another critical application gap between A2 vs D2 tool steel. While A2 steel is known for how A2 steel properties improve surface finish and precision and its good machinability, D2 tool steel can present D2’s processing difficulty and cost challenges for ultra-fine surface finish requirements. The high carbide content that gives D2 its superior wear resistance also makes it significantly harder to machine, grind, and polish to very fine tolerances. Achieving mirror-like finishes or intricate geometries with D2 can require more specialized equipment, longer processing times, and higher costs.

For applications involving miniature precision punch manufacturing, where component dimensions are extremely small and tolerances are tight, D2 tool steel’s dimensional stability test and optimization in miniature precision punch manufacturing becomes a critical factor. While D2 offers excellent dimensional stability during heat treatment, the actual machining of such tiny features from this tough material can be challenging, leading to potential issues with tool deflection or material tear-out. A2 steel, with its better machinability, might offer an A2 steel’s efficiency bottleneck in rapid prototyping and high-precision machining if not carefully considered, but generally fares better in initial processing stages for very fine features.

Furthermore, in industries like medical device manufacturing, D2’s stringent requirements and solutions for surface roughness in precision medical device molds are paramount. The high wear resistance of D2 is attractive for longevity, but achieving the required surface quality for medical components often necessitates extensive post-machining processes like lapping or polishing, which can be costly and time-consuming for D2.

In contrast, while A2 steel is not always the ultimate choice for extreme precision, A2 steel’s inadequacy in precision optical molds with extremely high dimensional stability requirements may arise if the application demands absolute minimal distortion or a level of surface perfection that even A2 struggles to maintain consistently without specific treatments. The overall processing services, including cutting and machining, offered by expert providers become vital here for managing tolerance control and achieving desired precision.

Critical Application Gap 3: Heat Treatment Stability and Microstructural Uniformity for Complex Geometries

Heat treatment is a transformative process for tool steels, determining their final mechanical properties. However, it also introduces potential pitfalls related to deformation and microstructural stability. This is where a critical application gap between A2 vs D2 tool steel often emerges, particularly for components with complex geometries or fine structures. Key strategies and errors in A2/D2 heat treatment deformation control in precision manufacturing are crucial considerations. Both steels are air-hardening, offering relatively good dimensional stability during hardening compared to oil-quenching steels. However, subtle differences can have significant impacts.

A2 tool steel generally exhibits good dimensional stability during heat treatment due to its lower alloy content compared to D2. However, A2 steel’s inadequacy in forming dies with strict heat stability requirements can surface when extremely complex shapes or very large sections demand exceptional uniform hardness and minimal distortion throughout the cross-section. Variations in section thickness can lead to uneven cooling and stress, impacting the final geometry.

D2 tool steel, with its higher carbon and chromium content, forms a significant amount of carbides, which contribute to its wear resistance but can also influence its microstructural response to heat treatment. The differences in A2 vs D2 microstructural stability in fine structure forming dies can be critical. D2’s microstructure can be more prone to carbide segregation if not properly manufactured and heat treated, potentially leading to variations in hardness or localized brittleness. For intricate dies with fine features, these microstructural non-uniformities can be detrimental to performance and tool life.

Furthermore, A2 and D2 in-process residual stress on final performance can be a major concern. The thermal cycles of hardening and tempering induce internal stresses within the material. While proper heat treatment practices, including stress relieving, can mitigate these, the inherent material characteristics of A2 vs D2 tool steel can dictate the ease and effectiveness of stress management. Companies that carefully forge their tool and die steel to ensure excellent heat treatment stability play a crucial role in mitigating these risks. Professional processing services are designed to address such challenges, providing solutions that consider the overall impact of manufacturing processes on the final material properties.

| Feature | A2 Tool Steel | D2 Tool Steel |

| Wear Resistance | High (Good balance with toughness) | Very High (Excellent for abrasive wear) |

| Toughness | Good (Better than D2 for impact) | Moderate (Lower than A2, prone to chipping) |

| Machinability | Good (Easier to machine and grind) | Fair (More difficult due to high carbide) |

| Surface Finish | Easier to achieve high precision and finish | More challenging to achieve ultra-fine finish |

| Heat Treat Dist. | Very Good (Lower alloy, less prone to warp) | Good (Higher alloy, careful control needed) |

| Applications | General purpose dies, punches, shear blades | High-volume dies, blanking, stamping, knives |

| Corrosion Res. | Moderate (Better than O1, but not “stainless”) | Moderate (Similar to A2, not truly corrosion resistant) |

| Cost | Typically lower than D2 | Typically higher than A2 |

Critical Application Gap 4: Environmental Factors and Surface Enhancement Compatibility

The operating environment and the need for surface enhancements introduce another layer of complexity when choosing between A2 vs D2 tool steel. While neither A2 nor D2 are considered corrosion-resistant steels, their inherent characteristics can influence their performance in specific industrial environments or their compatibility with advanced surface treatments.

Exploring application blind spots of A2/D2 in molds exposed to corrosive media is essential. In environments where tools are exposed to mild corrosive agents, humidity, or certain coolants, general cold work tool steels like A2 and D2 will eventually suffer degradation. For highly corrosive environments, specialized stainless tool steels would be necessary. However, for intermediate conditions, the microstructural differences between A2 vs D2 tool steel might slightly influence their susceptibility to surface degradation.

A more tangible gap emerges when considering surface enhancement coatings, such as PVD or DLC. These coatings are often applied to tool steels to further boost wear resistance, reduce friction, and sometimes offer a degree of corrosion protection. Here, D2 steel’s adhesion challenges when requiring PVD/DLC coating enhancement can become a factor. The surface preparation, chemical composition, and microstructural characteristics of the substrate steel play a crucial role in the adhesion and performance of these advanced coatings. While D2’s hardness provides an excellent base, its high carbide content can sometimes present challenges for optimal coating adhesion or uniformity if not properly pre-treated.

Conversely, surface treatment compatibility considerations for A2 vs D2 in precision connector molds are important. For precision components like connector molds, where surface finish and dimensional accuracy are critical, the choice of tool steel must align with the intended surface treatment. A2, with its relatively cleaner microstructure and better machinability, might offer a more consistent surface for certain coating applications, potentially leading to better adhesion or a more uniform coating layer. The professional customization services offered by experienced tool steel providers, including various process processing and steel type customization, can help navigate these complexities, ensuring compatibility with intended surface enhancements.

Critical Application Gap 5: Cost-Effectiveness, Supplier Expertise, and Long-Term Value

Beyond metallurgical properties, practical considerations like cost, supply chain reliability, and the expertise of the supplier constitute a critical application gap in selecting A2 vs D2 tool steel. Analysis of cost-benefit traps in A2 vs D2 material selection for customized industrial tools is vital for any business. While D2 generally offers superior wear resistance, making it attractive for high-volume production to extend tool life, its higher initial cost and increased processing difficulties can offset these benefits if the application doesn’t fully exploit its capabilities. Challenges of D2 steel when high mold life is required but budget is limited necessitate a careful evaluation of the total cost of ownership rather than just the upfront material cost.

This is where the role of a reliable tool steel supplier becomes indispensable. How precision mold steel suppliers bridge A2/D2 application gaps through professional customization is a key differentiator. Expert tool steel and mold steel solution providers offer not only a wide range of high-quality steel products, including both A2/1.2363 and D2/1.2379, but also possess extensive experience in the steel industry. They have a deep understanding of the characteristics and applications of various tool steels, enabling them to provide professional customization and offer affordable solutions based on a client’s intended use, production process, required strength, and budget.

Furthermore, how to optimize specific application inadequacies of A2 or D2 through professional processing and cutting services highlights the value of a comprehensive service provider. A company with reliable equipment, advanced production capabilities, and a professional technical team can offer services like machining and cutting, heating and forging, and heat treatment. These services can compensate for inherent material limitations, ensuring superior quality tool steel products and solutions. By stocking common tool steel products, they can also provide fast delivery times, meeting customers’ diverse needs and supporting efficient production schedules. Ultimately, choosing the right supplier is as critical as choosing the right steel, ensuring that the selection of A2 vs D2 tool steel delivers optimal long-term value and performance.

Conclusion

The debate between A2 vs D2 tool steel for precision manufacturing and industrial tools is not about declaring a single winner, but rather understanding their distinct strengths and weaknesses relative to specific application demands. We’ve explored five critical application gaps where their differences become most pronounced: their respective toughness under high impact, the challenges of achieving ultra-fine finishes and miniaturization, their heat treatment stability and microstructural uniformity in complex geometries, compatibility with environmental factors and surface enhancements, and the overarching considerations of cost-effectiveness and supplier expertise.

A2 tool steel excels where a balanced combination of wear resistance and good toughness is required, particularly where superior machinability and easier achievement of precision surface finishes are priorities. D2 tool steel, with its exceptional wear resistance, is the go-to choice for applications demanding extreme abrasion resistance and high compressive strength, provided that impact loads are managed, and the added processing difficulties are factored into the budget.

The key takeaway is that an informed decision regarding A2 vs D2 tool steel cannot be made in isolation. It requires a holistic assessment of the specific application’s demands, the operating environment, the desired tool life, and crucially, the support from an experienced tool steel solution provider. Leveraging the expertise of professionals who understand the nuances of various tool steels and offer comprehensive processing services—from customization to heat treatment—is essential for bridging these application gaps and ensuring optimal performance, durability, and a strong return on investment for any precision manufacturing or industrial tool project.

FAQ

Q1: What are the primary advantages of A2 tool steel over D2 in precision manufacturing?

A1: A2 tool steel generally offers better toughness, making it less prone to chipping under moderate impact loads. It also has superior machinability and grindability, which can lead to easier processing and better surface finishes for precision components. Its dimensional stability during heat treatment is also excellent, which is crucial for intricate parts.

Q2: When should I definitively choose D2 tool steel instead of A2 for industrial tools?

A2: You should choose D2 tool steel when your application demands exceptional wear resistance and high compressive strength, especially in highly abrasive environments. D2 excels in scenarios where tool longevity against friction and material removal is the primary concern, such as in high-volume blanking, stamping, and forming dies where wear is the dominant failure mode.

Q3: How does heat treatment differ for A2 vs D2 tool steel, and why is it critical for precision?

A3: Both A2 and D2 are air-hardening steels, meaning they exhibit good dimensional stability. However, D2’s higher alloy content and carbide volume require more precise control during heat treatment to avoid excessive distortion or carbide segregation. Achieving excellent durability, cutting performance, and heat treatment stability is critical for precision, and professional solution providers carefully forge these steels to ensure these properties. Errors in heat treatment can lead to unacceptable deformation or compromised mechanical properties, making expert processing crucial.

Q4: Can a tool steel supplier help me decide between A2 vs D2 tool steel for a specific application?

A4: Absolutely. Reputable tool steel suppliers have teams of experts with extensive experience and deep understanding of various tool steels. They can provide professional customization and offer tailored solutions based on your intended use, production process, required strength, and budget. They can guide you through the complexities and help bridge any application gaps by recommending the most suitable material and processing services.

Q5: What are the cost implications when choosing between A2 vs D2 tool steel?

A5: D2 tool steel typically has a higher material cost than A2 due to its higher alloy content. Furthermore, its increased hardness and wear resistance make it more challenging and costly to machine, grind, and finish to tight tolerances. While D2’s extended tool life in abrasive applications can justify the higher initial investment for high-volume production, A2 often offers a more cost-effective solution for applications where its performance capabilities are sufficient, considering both material and processing costs.

If you enjoyed this blog on mechanical parts processing, don’t forget to join me on social media for more insights, updates, and community discussions.

📘 Facebook – Connect with me here

Let’s keep exploring, learning, and growing together. Thanks for reading, and see you in the next post! 🚀